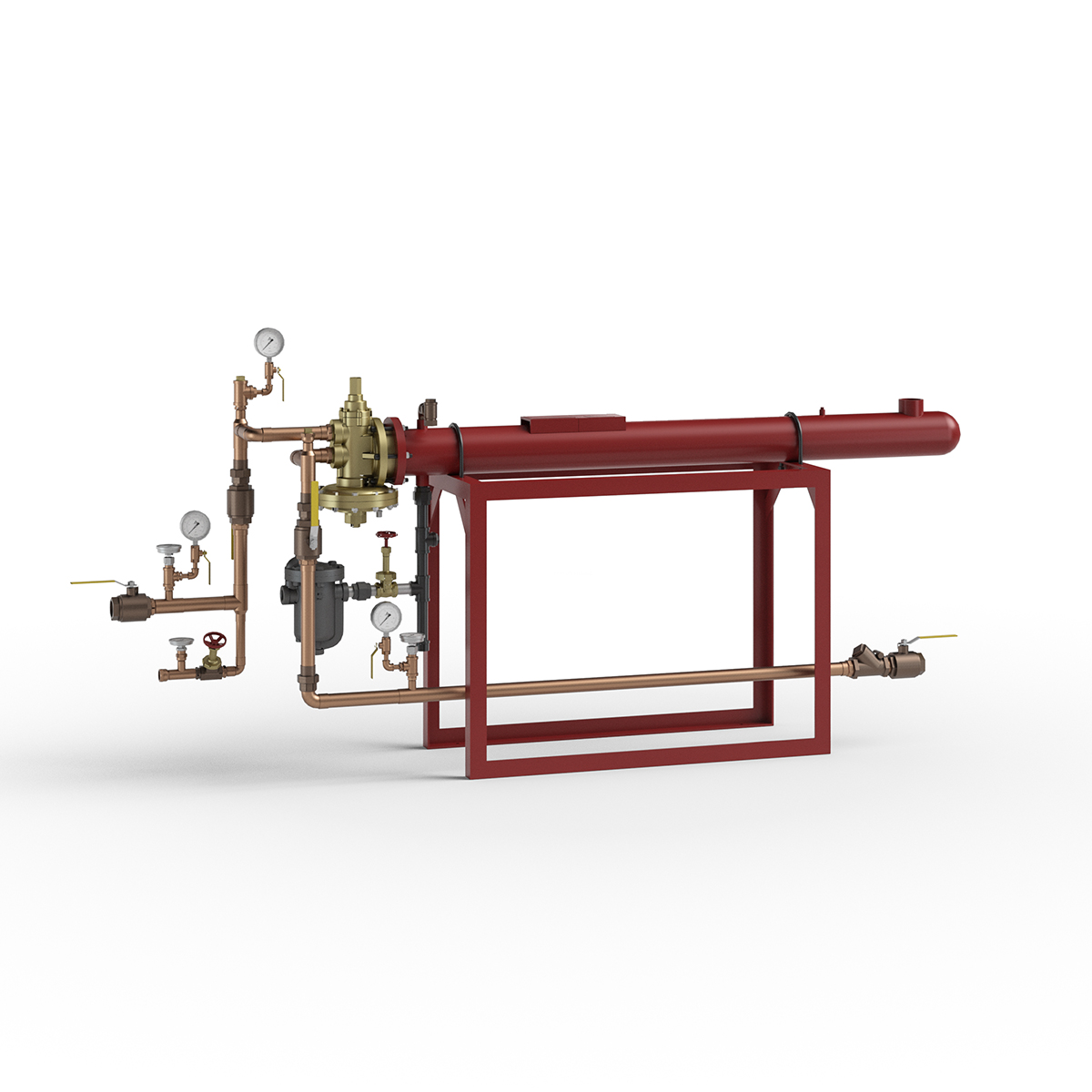

FLO-RITE-TEMP® PRE-PIPED FOR THERMOSTATIC CONTROL OF NON-RECIRCULATING HOT WATER SYSTEMS

Flo-Rite-Temp Pre-Piped for Thermostatic Control of Non-Recirculating Hot Water Systems are factory-built water heating packaged solutions inclusive of a shell & tube heat exchanger fitted with an integral control valve for water heating and system temperature control.

The feed forward design instantly determines downstream hot water demand and directs cold water through the heat exchanger. Water is heated above legionella survival temperatures with constant pressure steam and then blended with a proportional amount of cold water to set point temperature.

Flo-Rite-Temp Pre-Piped for Thermostatic Control of Non-Recirculating Hot Water Systems are available with single wall or double wall heat exchangers in 4 standard sizes each with a parallel/redundant option and can be customized to suit.

PRODUCT SPECIFICATIONS

| Model | Flow Capacity | Hot Water Outlet Connection Size |

| FRT535 | 35 gpm (132 lpm) | 1-1/2″ (38 mm) |

| FRT665 | 63 gpm (238 lpm) | 2″ (51 mm) |

| FRT8120 | 120 gpm (454 lpm) | 3″ (76 mm) |

| FRT535DW | 35 gpm (132 lpm) | 1-1/2″ (38 mm) |

| FRT665DW | 63 gpm (238 lpm) | 2″ (51 mm) |

| FRT8120DW | 120 gpm (454 lpm) | 3″ (76 mm) |

| FRT535P | 70 gpm (265 lpm) | 2″ (51 mm) |

| FRT665P | 126 gpm (477 lpm) | 3″ (76 mm) |

| FRT8120P | 240 gpm (908 lpm) | 3″ (76 mm) |

| FRT535DWP | 70 gpm (265 lpm) | 2″ (51 mm) |

| FRT665DWP | 126 gpm (477 lpm) | 2″ (51 mm) |

| FRT8120DWP | 240 gpm (908 lpm) | 3″ (76 mm) |

RESOURCES

INSTALLATION AND MAINTENANCE

Flo-Rite-Temp Accumulation Piping System

Flo-Rite-Temp Clean In Place Instructions

Flo-Rite-Temp Radiant Heat or Closed Loop System Piping

Flo-Rite-Temp Recirculation System Piping

Flo-Rite-Temp Sizing Instructions

Flo-Rite-Temp Start-Up Procedure

DRAWINGS – SINGLE WALL MODELS

DRAWINGS – DOUBLE WALL MODELS

Data Sheet – Flo-Rite-Temp Sizing Chart

Data Sheet – Flo-Rite-Temp Double Wall

Data Sheet – Flo-Rite-Temp Single Wall

DATA SHEETS

Storage Heater Replacement for Shower Use (Shanghai Gaoyang International Tobacco) Case Study